Quality & ISO 9001:2015

Our commitment to quality is embedded in every coil and transformer winding we produce.

Winding Procedures

Documented winding processes with operator checklists for consistency and accuracy.

Raw Material Inspection

Copper purity verification and insulation quality checks before production begins.

Dimensional Checks

Precision dimensional checks and insulation integrity tests during production.

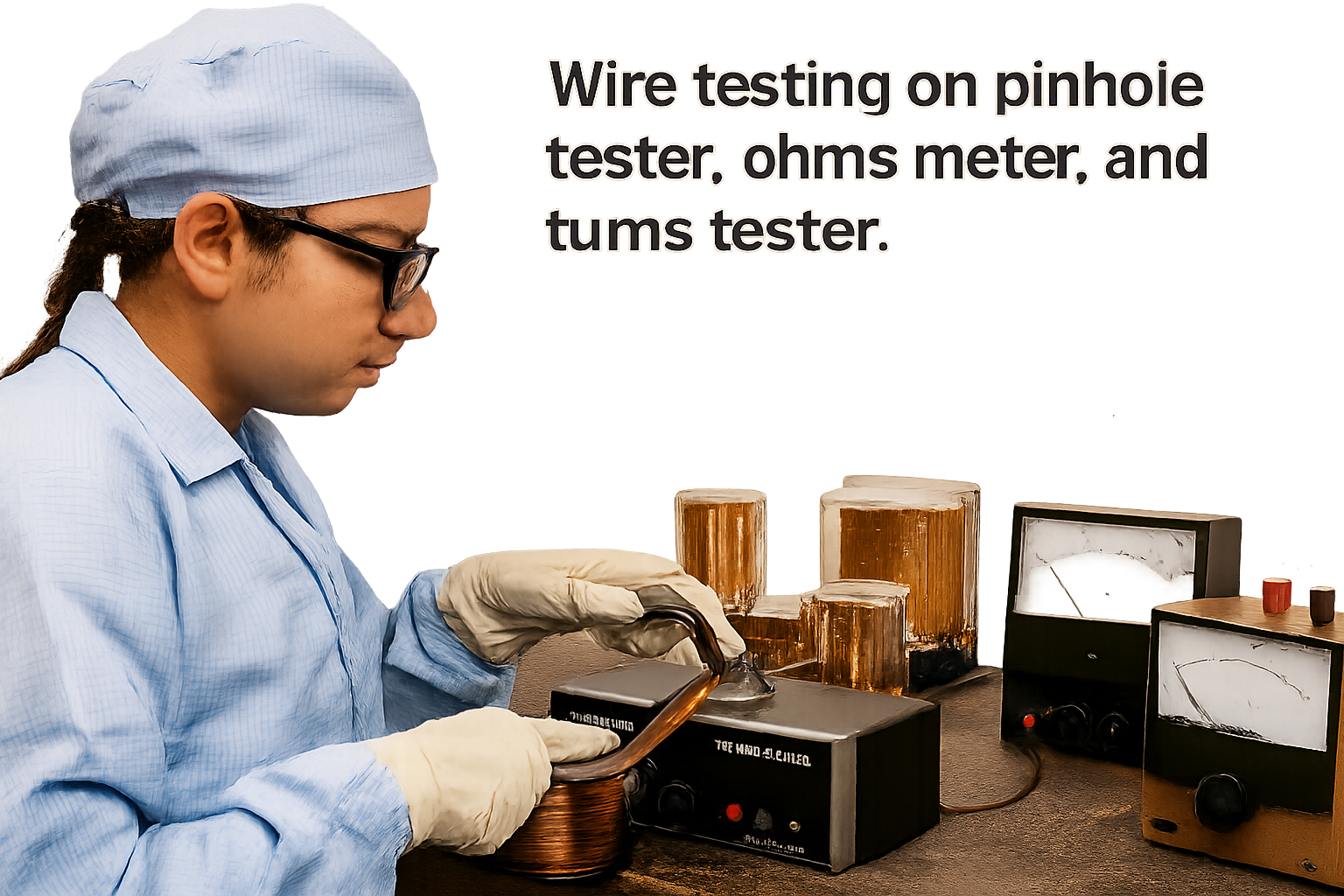

Electrical Testing

Inductance, resistance, and thermal performance tests for reliable coil operation.

Final Inspection

Outgoing finished goods inspection with traceable QA records and ISO compliance.

Our processes are aligned with ISO 9001:2015